About Inventor

An ingenious mechanical engineer, Late. Mr. Prabhakar Gogate was an industry veteran of the Clamping World. Being first-generation entrepreneur, he is the founder of Jupiter Industrial Works Thane. Leading the company with exceptional analytical skills, he led the company to enormous heights of success. The initial factory started falling-short to convene with rising demands of clamps, which created urgency for a solution to cut-short workspace but significantly achieve multi-fold production. With adept technical knowledge and strong emphasis on engineering, he had a systematic approach in solving problems, he innovated first patent of Compact Duplex Power Press (CDPP). Ever since the inception, CDPP has been a principal machine at all our factories.

Mr. Prabhakar Gogate

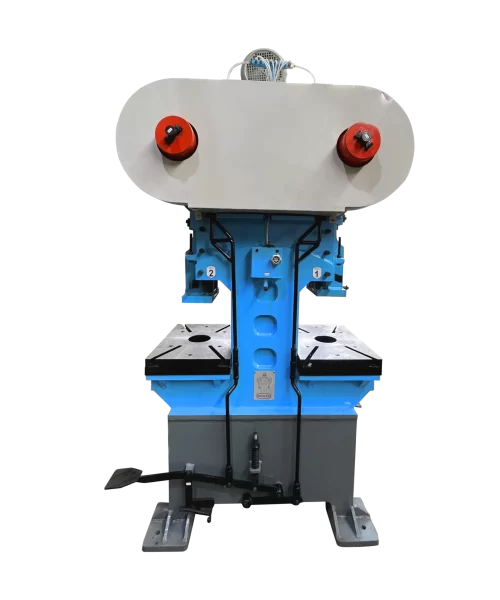

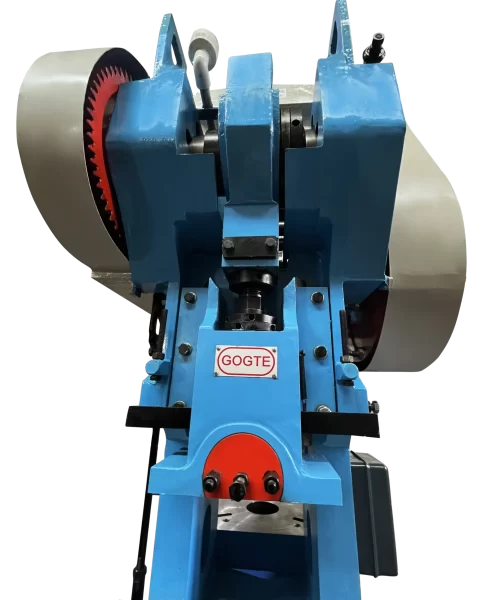

About Compact Duplex Power Press CDPP

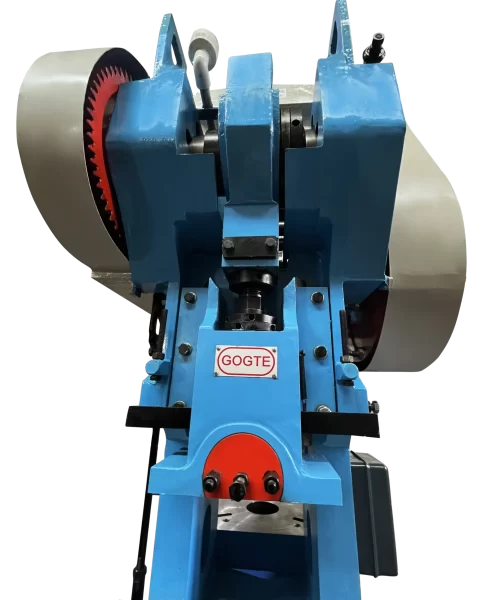

The innovative novel design of Compact Duplex Power Press comprise two power presses constructed in one body frame on its opposite sides. With common single motor drive in lieu of two motors employed in conventional two presses. Consisting common flywheel, gear box, single body frame, switch box and automatic self-Hydrodynamic lubrication system, it saves investment for machines, workspace, cost or rent as capital gains along with continuous saving in Power bills while in use. This design nearly saves 40% of workspace as compared to using Two Conventional machines of the Same capacities.

The innovative novel design of Compact Duplex Power Press comprise two power presses constructed in one body frame on its opposite sides. With common single motor drive in lieu of two motors employed in conventional two presses. Consisting common flywheel, gear box, single body frame, switch box and automatic self-Hydrodynamic lubrication system, it saves investment for machines, workspace, cost or rent as capital gains along with continuous saving in Power bills while in use. This design nearly saves 40% of workspace as compared to using Two Conventional machines of the Same capacities.

Why CDPP?

Low Maintenance

Hardened and Grounded components

Reduced Material Handling

Power Saving

Space Saving

Improved Monitoring of Productivity

Workspace saving

Saving in Movement

Saving in Motive Power by Economical use

Tool Setting Convinence and Flexibility

In-Built Total Auto Lubrication system

Multifold Productions Ahieved

Hardened and Grounded components

Low maintenance

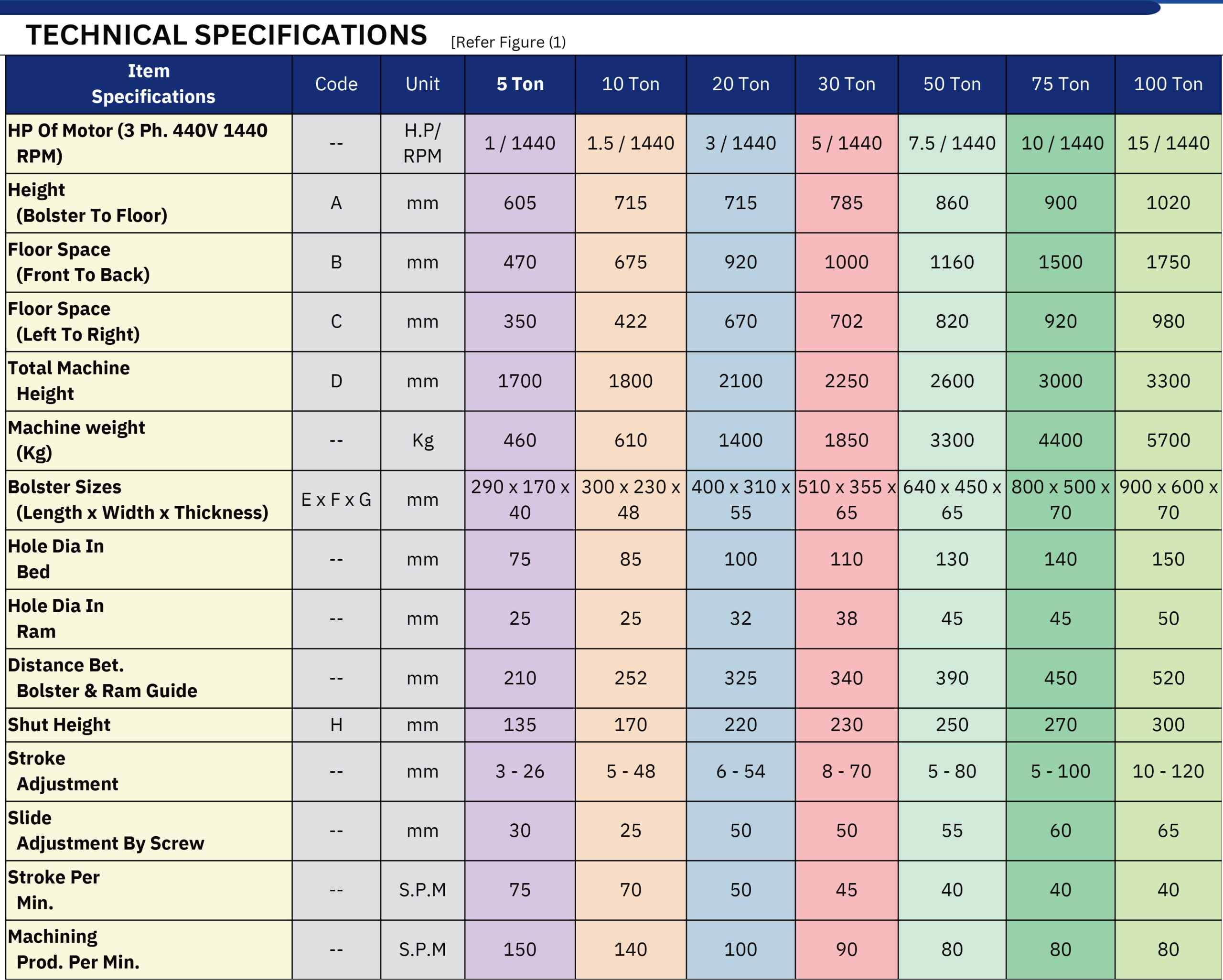

Technical Feature